Game Changing Solar Energy Technology

- 20/04/22

- Business of Solar

The greater power output and efficiency of new solar modules coming onto the global market will help the world to achieve a major shift to renewable energy.

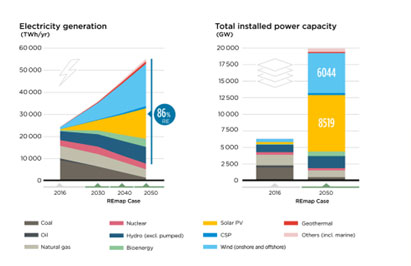

Renewable energy today accounts for less than one-sixth of primary energy supply, but is forecast to grow to nearly two-thirds by 2050, the International Renewable Energy Agency (IRENA) says in its Global Energy Transformation Report.

In the report it also says solar energy’s total installed power capacity will reach 8.52 terawatt by 2050.

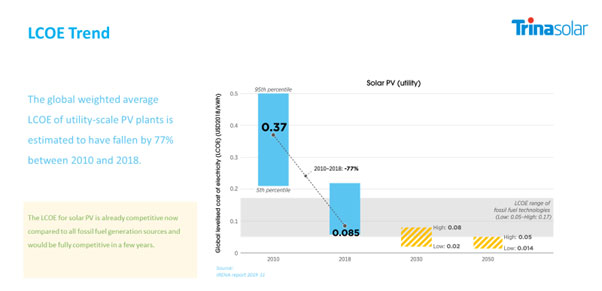

“There is a lot of potential for the growth of solar. If you look at the levelized cost of electricity (LCOE) for solar, it has fallen and is now very competitive to the cost of fossil fuels,” Trina Solar product & marketing head for Asia Pacific region Cheong Boon Lim said in a recent webinar held for India audience.

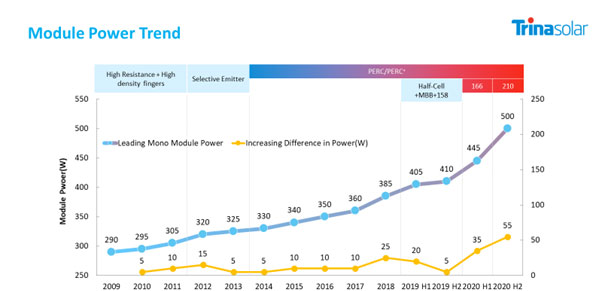

LCOE has fallen partly because the amount of power each module can produce has steadily increased. Modules in 2009 were 290W. Then in early 2019 modules were 405W and more recently we have seen module power increase further to 500W.

The increase in module power is due to technological break-throughs. “In the last three to four years, mono PERC has become more accepted. Then in the last two years we at Trina Solar have also started to adopt the half-cut cell technology and multi-busbar technology. The wafer size has also increased from 158mm diameter to 166mm and now 210mm,” says Lim.

Our newest modules, the Vertex back-sheet and Vertex bifacial modules, uses 210mm diameter wafers to further increase the power we can pack into a solar module, he says.

There are another three key technologies, incorporated into the Vertex modules, that account for the module’s higher power output.

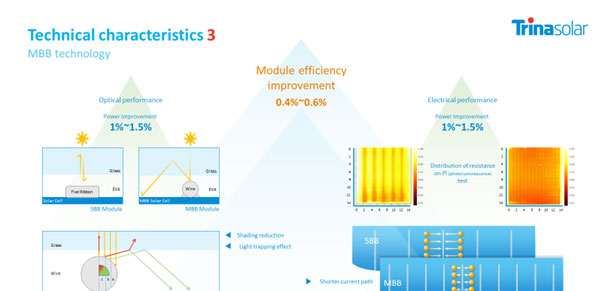

Lim says: “The multi-bus bar (MBB) technology in this new range of modules have 10 bus bar which we see is the optimal number of bus bars for our module design. We are also using a wire ribbon for the MBB rather than a flat ribbon. Wire ribbon reduces shading and increases the light trapping to increase performance of the cells. The benefit of MBB technology is it creates a shorter current path for the electricity, so we have less series resistance and less power loss.”

Vertex modules also have one-third cut cells. “We have been able to produce these one-third cut cells using new non-destructive cutting technology. Trina Solar has been using half-cut cell technology for some time, so now we have stepped up to one-third cut cells,” says Lim.

“We could have produced one-quarter cut cells and also achieve a very high power bin, but the open circuit voltage (VOC) would also increase tremendously, which would then impact on number of modules per string and that in turn would increase the cost on the BOS (balance of system cost). The manufacturing cost and complexity would also increase, as it involves more manufacturing processes,” he adds.

Lim says: “For the one-third cut cells we are using a new non-destructive cutting technique. The technique uses one movement and it is done at low temperature. With this technique we get very smooth surfaces, with no cracks, after cutting.”

The other key innovation is the ‘high encapsulation’ technology, which reduces the space between each cell so we can increase module efficiency by reducing module size. Traditional modules have ~2mm spacing between each cell, “but Trina is having less than 0.5mm spacing between each cell.”

Trina Solar is now ramping up production of the Vertex modules and aims to achieve 5GW of production by year-end.

Relevant Topics

Smart Energy Solutions

delivered straight to your inbox