How bifacial PV modules work: Factors that affect rear side power.

- 22/10/07

- Reliability,Customer Value,Panel Talk and Technology

Bifacial technology for solar panels has existed nearly as long as solar panels themselves. However, it was not until 2018 when this technology was effectively deployed massively in the industry.

Therefore, we can say that bifacial technology is a relatively new development in solar panel design that presents both opportunities and challenges. Bifacial solar modules are modules that generate energy on both their front and rear sides, based on solar cells with two active sides.

Bifacial technology principles

While the energy production of traditional monofacial solar panels is relatively easy to forecast, bifacial panels provide a bit more of a challenge. This is because the energy production of bifacial solar panels depends not only on the relatively straightforward absorption of direct sunlight on the front side, but also on the less straightforward influx of reflected or diffuse light on the rear side.

The general formula for determining the total energy generation of a bifacial solar panel is the sum of the energy output on the front side and the energy output on the rear side. However, as the energy output on the rear side is much more difficult to calculate, the total calculation of bifacial power output requires some industry innovation.

In most cases, industry experts calculate the power generation on a bifacial panel’s rear side in terms of the “bifacial gain,” as a fraction of the energy produced by the front side of the module. Since the light reaching the module’s rear side behaves differently than the light reaching the front side, bifacial modules must be understood in terms of “bifacial ratio” (i.e., the ratio of irradiance on the rear to that on the front) and “module bifaciality” (i.e., the ratio of the front and rear sides’ energy conversion efficiency).

Rear side irradiation also depends upon factors like sunlight reflected from the ground and sunlight diffused through the atmosphere. When trying to understand the level of irradiation reflected from a solid surface, industry professionals need to take into account the surface reflection coefficient, which is known as an “albedo.” Other relevant factors include shading, module height, and the distance between different module rows (pitch).

Monofacial vs bifacial solar PV modules

At cell structure level, traditional monofacial cell back surface is an aluminum back surface field, which blocks light absorption on the back. Optimizing bifacial cells requires adopting a bifacial alkali texturization process to guarantee the same light-trapping structure on both sides.

Different cell types and technologies have different bifaciality rates, which defines the ratio of the front-side efficiency over the rear-side efficiency. N-type cell technologies such as HJT and TOPCon have higher bifaciality compared to PERC.

Monofacial modules usually include a solid backsheet which blocks any possibility of light capturing on the rear side.

However, with bifacial panels, the back side requires a translucent material that allows sunlight to pass through. Many bifacial panel designs, including Trina Solar’s, use a double glass structure for this purpose.

Manufacturers tend to prefer glass panels on both the front and rear sides of a bifacial module because these designs tend to better transmit light and are more resistant to inclement weather, moisture permeation, corrosion, and more excellent mechanical load ability. For this reason, Trina Solar’s state-of-the-art bifacial Vertex solar modules utilize innovative glass-glass designs to maximize total power generation.

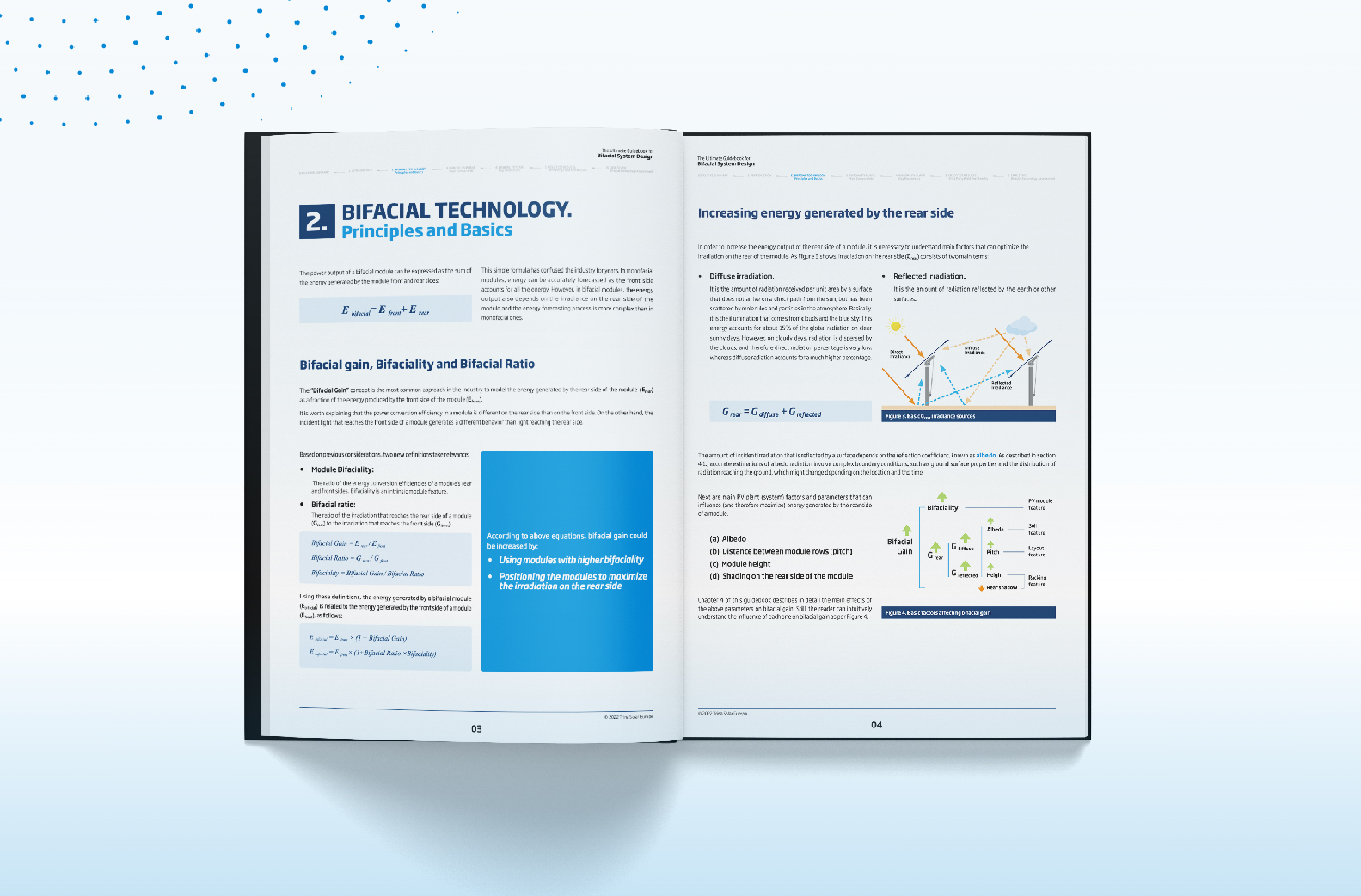

Trina Solar’s Ultimate Guidebook for Bifacial System Design

To learn more about key factors to consider when planning solar power stations with bifacial modules, and the benefits these modules can bring to any solar project, download Trina Solar’s free Ultimate Guidebook for Bifacial System Design today!